Green Hydrogen System Solutions

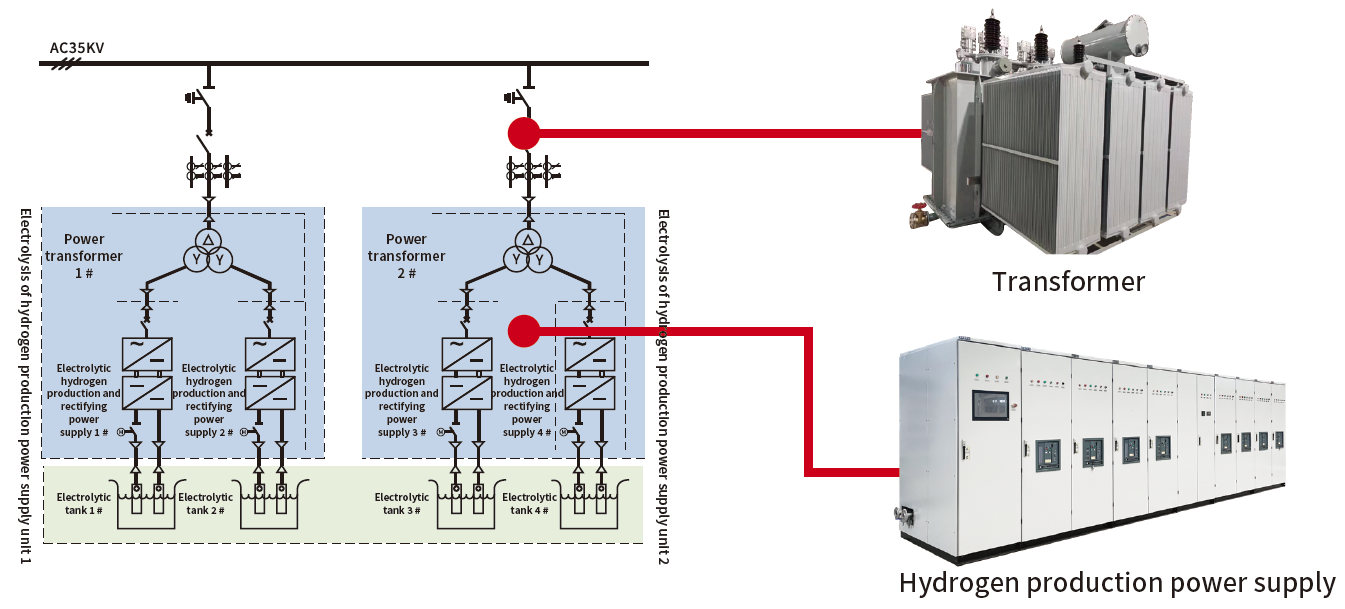

Hydrogen Power Supply

The alkaline electrolyzer has a relatively high efficiency at around 80°C, while the temperature of the electrolyzer has a high inertia. The hydrogen power supply is able to adjust the electrolyzer power supply to maintain the temperature at around 80°C during grid fluctuations to achieve higher efficiency.

High-efficiency Hydrogen Power Supply

-Matching the characteristics of the electrolytic cell, high efficiency of the complete set

-Quickly follows the power changes of green power, making full use of new energy power and reducing the demand for electricity from the conventional grid

-Low harmonics and high power factor, reducing pollution to the grid

-Reactive power compensation capability, providing reactive power support to the grid

-High reliability and long life span

Hydrogen production power supply parameter table

No. | Model and Specification | Data |

1 | Installation environment | Indoor / Container / Outdoor |

2 | Grid input voltage | 10kV/35kV(Transformer design) |

3 | Grid voltage range | ±10% |

4 | Rated grid frequency | 50Hz |

5 | Grid frequency range | 45~55Hz |

6 | Total current distortion rate of grid side currents | <3% |

7 | Grid side power factor | >0.99 |

8 | Grid side reactive power compensation function | Yes |

9 | Maximum power output | 6000kW |

10 | DC output voltage range | 0~850V |

11 | Output current range | 0~8000A |

Pump, compressor and fan drive control systems

Energy-efficient drive control system offers customers a system-level solution by combining high-efficiency permanent magnet synchronous motors with high-performance vector inverters, simplifying procurement and commissioning and reducing corresponding costs.

Performance characteristics of green hydrogen production control

-High efficiency hydrogen production control pump, compressor and fan drive control system

-Self-fan-cooling design of the motors, which can be driven by inverters without forced ventilation and cooling, excellent constant torque operation at low speeds, wide speed range and high efficiency in the full speed range

-High power factor, high system operating efficiency and low maintenance costs

-Fast dynamic response, intelligent frequency control, safe, stable and reliable

Main Technical Parameters of the Low Voltage Drive Control System | |||

Motor | VFD | ||

Name | Parameter | Remark | |

Input Voltage | 220/380V, 380/660V | 22/380V, 380/660V | Available to customized |

Capacity / Power range | 1.1-315kW | 1.5-400kVA | |

Topology | Asynchronous motor, PMSM | AC-DC-AC/(two levels) | |

Number of motor poles | 2/4/6/8/10P | Available to customized | |

Output frequency range | - | 0-50/60/120Hz reset-able | |

Speed regulation accuracy | - | 0.01Hz | |

Ingress Protection | IP54, IP55, IP56, IP66 | ||

Applicable motor types | AC asynchronous motor, PMSM | ||

Cooling method | IC411 | FA | |