Medium Voltage Static Var Generator (SVG)

MV SVG are using Modular Multilevel Converters (MMC) technology based on standard H-Bridge Power Module and Voltage Source Converter.

With its advanced topology and control algorithm, MV SVG offers the best shunt reactive power compensation, harmonic compensation, and unbalance correction in energy and industrial applications. A MV SVG offers better dynamic performance than a SVC, in particular a faster response time as well as the ability to generate or absorb reactive power when the grid voltage drops. It therefore helps increase reliability and availability of grid operation.

No need for step-up transformer, Medium Voltage Static Var Generator can be directly connected to medium voltage network from 3.3kV up to 35kV with the rated reactive power of 30Mvar per unit.

HOW IT WORKS ?

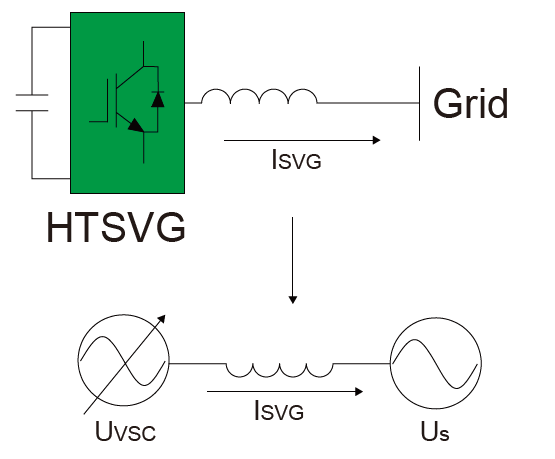

Static Var Generator is based on Voltage Source Converter (VSC) technology. VSC consists of Insulated Gate Bipolar Transistor (IGBT) as fully controlled power semiconductor device.

VSC produces single or three phase AC voltage from a DC input voltage. The VSC generated voltage is coupled to the source voltage through a Pulse Width Modulation (PWM) reactor. By varying the magnitude of AC terminal voltage of VSC, reactive power exchange takes place between the VSC and the AC source.

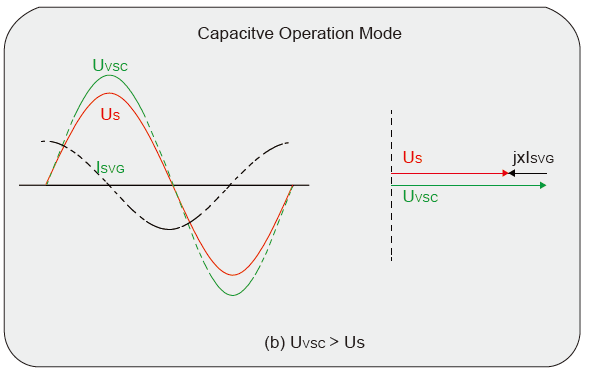

If the magnitude of VSC voltage is more than the AC source voltage, capacitive current flows from supply voltage to VSC and the SVG generates capacitive reactive power.

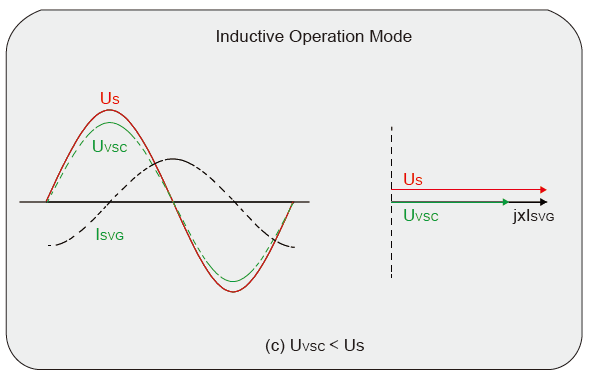

If the magnitude of VSC voltage is less than the AC source voltage, inductive current flows from supply voltage to VSC and the SVG generates inductive reactive power.

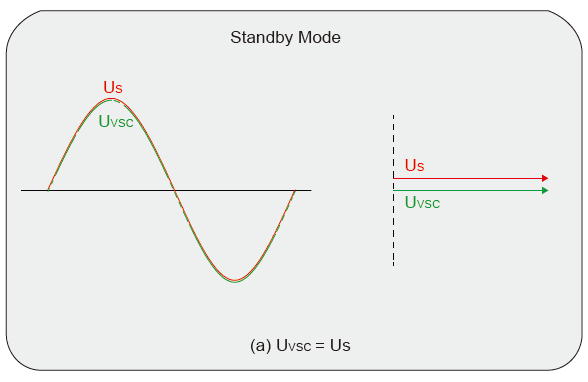

If the amplitude of VSC voltage is equal to the AC source voltage, no current flow happens, and the SVG does not generate reactive power.

HARDWARE & TOPOLOGY

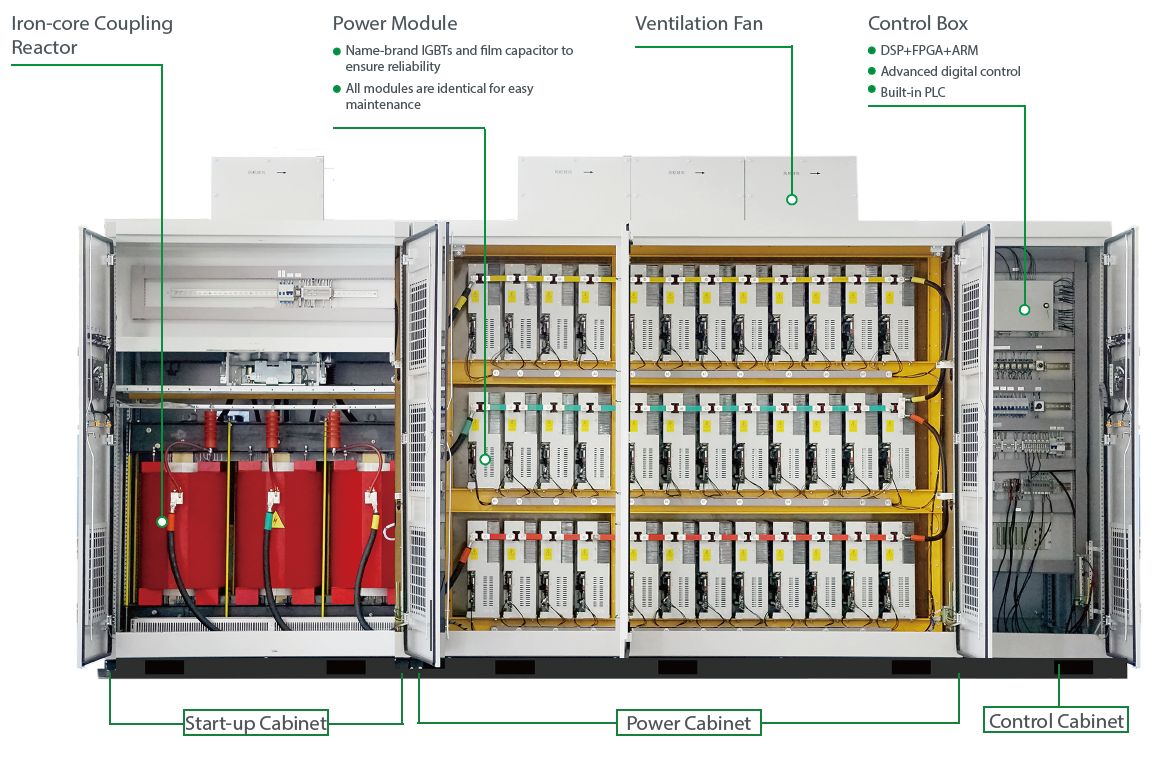

MV SVG consist of one start-up cabinet, power cabinet(s), and one control cabinet for easy transportation and electrical isolation between primary circuit and secondary circuit.

The start-up cabinet consists of incoming cable terminals, output current transformers, precharging resistors, precharging contactor, voltage detector, coupling reactor.

For MV SVG with rated voltage above 22kV, the start-up circuit would be located outdoor and air-core coupling reactors will be used.

The power cabinet(s) comprise of power modules. The modules in the same phase are connected in series. The three phases are connected in wye connection, or in delta connection when unbalance correction is needed.

Robust technological solution for heavy industry load process:

-Electric Arc Furnaces: Electric Arc Furnaces (EAF), Ladle Furnaces (LF), Submerged Arc Furnaces (SAF) and Open Bath Furnaces (OBF)

-Rolling mills: Direct Online Motors (DOL), Variable Frequency Drives (VFDs) and DC Drives

-Mining industry: Heavy machines with large electric motors in mines

-Other heavy industrial loads, such as pumps, harbor cranes, woodchippers, and conveyor belts, Oil & Gas, Solar plant, Wind farm, Chemical & Cement industry, etc.